Best Snowboard FIlms 2025–2026: The Heaviest New Snowboard Movies Dropping This Winter

From Forest Bailey’s creative street parts to Burton’s global backcountry odyssey, these

Oxbow’s journey toward sustainable, locally-made technical outerwear.

WORDS Alba Pardo

Founded in France in 1985, Oxbow built its reputation in the surfing and snowboarding worlds by blending quality, performance, and style. Today, the brand is doubling down on its local production ambitions, creating collections within Europe and, where possible, in France. In this interview, Aurélien Silvestre, Product Manager at Oxbow, delves into the iconic brand’s commitment to sustainable production and their ongoing journey to reconnect with the brand’s origins and shares the complexities and rewards of upholding Oxbow’s core values – craftsmanship, sustainability, and authenticity – while evolving their technical outerwear line to meet modern demands.

Aurélien, thank you for joining us today. Could you start by telling us about your role at Oxbow and what makes this brand’s mission so compelling?

Thank you, Alba! I’ve been with Oxbow as a Product Manager for over four years now. I joined shortly after the brand was bought back by two independent owners, which was exciting for me because Oxbow was returning to its roots as an independent French brand. My background includes working for Billabong on outerwear collections, but Oxbow offered something unique – an authentic, long-term project with a sustainable approach. The brand’s owners wanted to bring Oxbow back to its 80s and 90s values, prioritizing quality, storytelling, and sustainability.

Sustainability is such a focus for action sports brands today. What does sustainability mean at Oxbow, and how are you implementing it in your product lines?

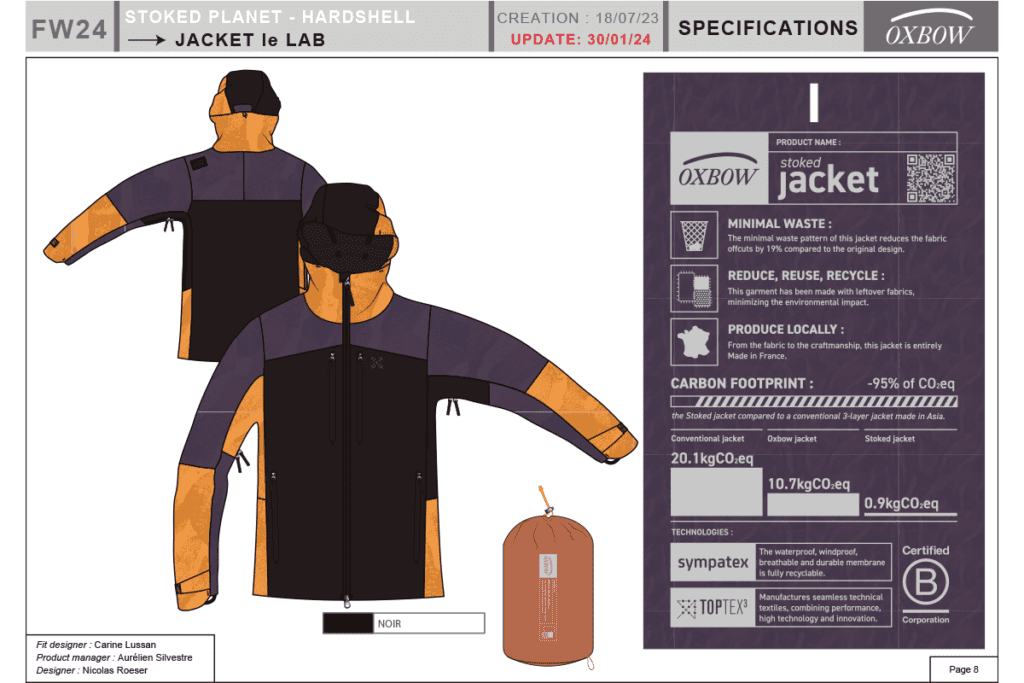

We’re very mindful of our environmental impact and strive to improve with each collection. We don’t claim to “save the world,” but we take steps to minimize our impact where possible. For example, we recently achieved B Corp certification, which reflects our commitment to sustainability. Our mantra is to be “the best for the world,” focusing on continuous improvement. We produce a portion of our collections in Europe, including France, using locally sourced materials. This approach supports the local economy and reduces our carbon footprint. It’s also a way to honor Oxbow’s origins as a French brand and reconnect with the communities that initially built our legacy.

It sounds like producing locally has its challenges. Can you elaborate on those, especially in terms of design and cost?

Absolutely. Producing locally, particularly technical outerwear, is complex. In Asia, you have access to vast fabric options, advanced technology, and lower production costs. In Europe, these resources are limited, and costs can be up to four times higher. For example, a snow jacket is significantly more expensive to produce in Europe. However, by producing here, we’re investing in social responsibility, quality, and craftsmanship. We also work closely with local suppliers to develop every aspect of our products, from fabric to finish, which makes the final product feel more authentic. It’s an uphill battle in terms of logistics and cost, but we’re committed to this approach.

Speaking of authenticity, how does that factor into Oxbow’s designs and brand identity?

Authenticity is central to our approach. We often look to our 80s and 90s catalogs for inspiration, revisiting classic styles with a modern twist. For instance, our “Collector” collection focuses on retro-inspired pieces that remind people of the original Oxbow aesthetic. Producing these items in France adds another layer of authenticity, as we work with factories and people who’ve been in the industry for years and who have their own connections to the brand. Our designs reflect a genuine respect for Oxbow’s heritage and the communities we support.

How has the market reacted to these locally-produced and higher-priced collections?

The response has been great, though we’re aware of the price sensitivity. Customers who understand our story and the craftsmanship behind each item appreciate the value. Our Collector collection, for instance, resonates with long-time fans and younger customers drawn to the retro style. That said, it’s a small percentage of our overall production; most of our pieces are still manufactured in Asia. However, our ultimate goal is to make local production a bigger part of Oxbow’s offerings as we scale and improve costs over time.

Let’s talk about the technical side. How do you approach the design and testing of your technical outerwear?

Testing and quality are non-negotiable, especially for technical products. We collaborate closely with our team of athletes and ambassadors, who provide invaluable feedback on the products’ performance in real conditions. They help us refine details and improve each collection. For example, our recent snow jacket went through multiple rounds of testing, with feedback from riders helping us enhance the fit, insulation, and durability. We’re now at a stage where our products are reliable and can compete with other high-end outerwear, which is a big accomplishment given we’ve only been producing these collections for three years.

You mentioned earlier about the challenges in producing technical pieces in France. How do you overcome these hurdles while maintaining the quality and functionality of your products?

It’s a team effort, really. We work hand-in-hand with our production partners, sharing feedback from our riders and testing prototypes thoroughly. For example, our recent snow jacket collection had some design tweaks, like improving the hood fit for better helmet compatibility. We are continuously making these small adjustments to enhance comfort and functionality, which is critical for performance outerwear.

So where do you see Oxbow going next?

Our goal is to expand our local production capabilities and make it accessible to a wider customer base. We’re exploring ways to create more basic, affordable items made in France, which would allow us to increase our volume and support local economies even further. We want this local, sustainable approach to become a hallmark of Oxbow, while still delivering quality and authenticity. And ultimately, we hope to inspire other brands to rethink their production strategies in favor of more local, responsible practices.

Thank you for sharing these insights, Aurélien. It’s inspiring to see a brand with such a deep commitment to authenticity and sustainability. Congratulations on all you’ve achieved so far!

Thank you, Alba! It’s been a rewarding journey, and we’re excited to continue moving forward. We appreciate the opportunity to share our story with you and your readers.

From Forest Bailey’s creative street parts to Burton’s global backcountry odyssey, these

With the Olympic qualification window fully open, this winter is less about

Sign up for the very best in snowboard culture, get notified of prize drops, and receive our weekly essential news hit: The Friday Dump.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_gtag_UA_189035576_1 | 1 minute | This cookie is set by Google and is used to distinguish users. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |

| CONSENT | 16 years 4 months 12 hours | These cookies are set via embedded youtube-videos. They register anonymous statistical data on for example how many times the video is displayed and what settings are used for playback.No sensitive data is collected unless you log in to your google account, in that case your choices are linked with your account, for example if you click “like” on a video. |

| Cookie | Duration | Description |

|---|---|---|

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| test_cookie | 15 minutes | This cookie is set by doubleclick.net. The purpose of the cookie is to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| yt-remote-connected-devices | never | These cookies are set via embedded youtube-videos. |

| yt-remote-device-id | never | These cookies are set via embedded youtube-videos. |

| Cookie | Duration | Description |

|---|---|---|

| _pk_id.43969.7c7f | 1 year 27 days | No description |

| _pk_ses.43969.7c7f | 30 minutes | No description |